Concrete Coatings & Restoration

High standards are the norm in the aviation and aerospace industry, which demands the same level of excellence in its facility floor coatings. From aesthetics to durability and safety, the right flooring in aviation and aerospace operations can make all the difference in the overall success of day-to-day operations.

Concrete floors are a common sight in facilities that store and repair commercial or government aircraft. When bare and unsealed, concrete is porous and can easily soak up jet fuel, Skydrol®, solvents and other aircraft fluids, eventually causing the concrete to break down over time. The more corrosive the substance, the more likely it is that floors will become uneven and damaged, posing a safety threat to technicians, pilots and other maintenance and hangar personnel.

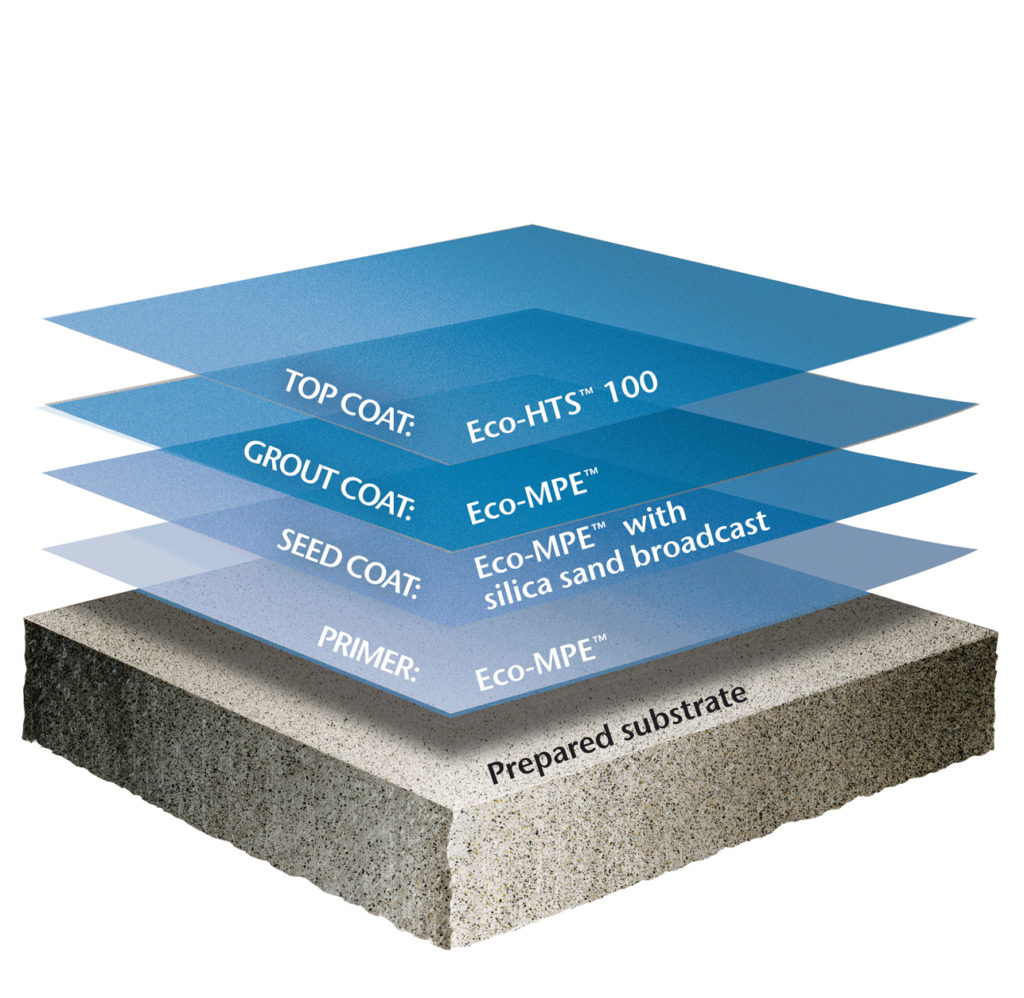

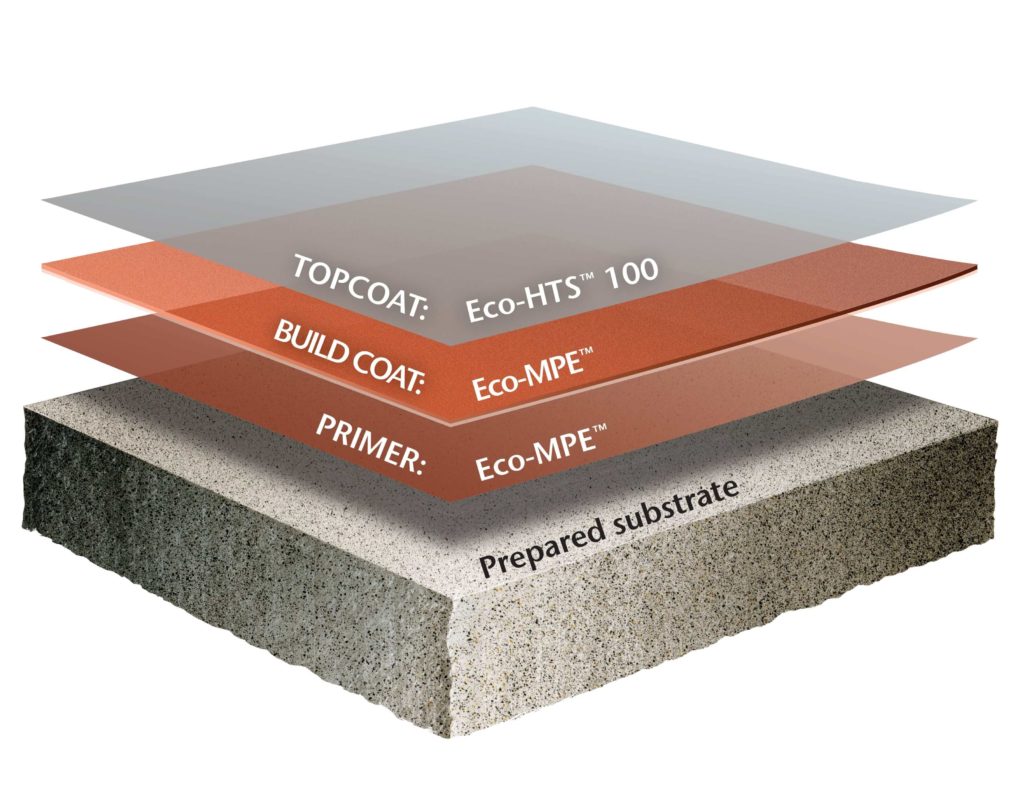

A four-coat, nomial 1/16” system, used to help withstand the high demands of a hard working facility, with a silica sand broadcast for added texture and durability, topcoated with Eco-HTS™ 100 for chemical resistance and its aliphatic properties.

Key Features of Eco-ShopFloor™ System

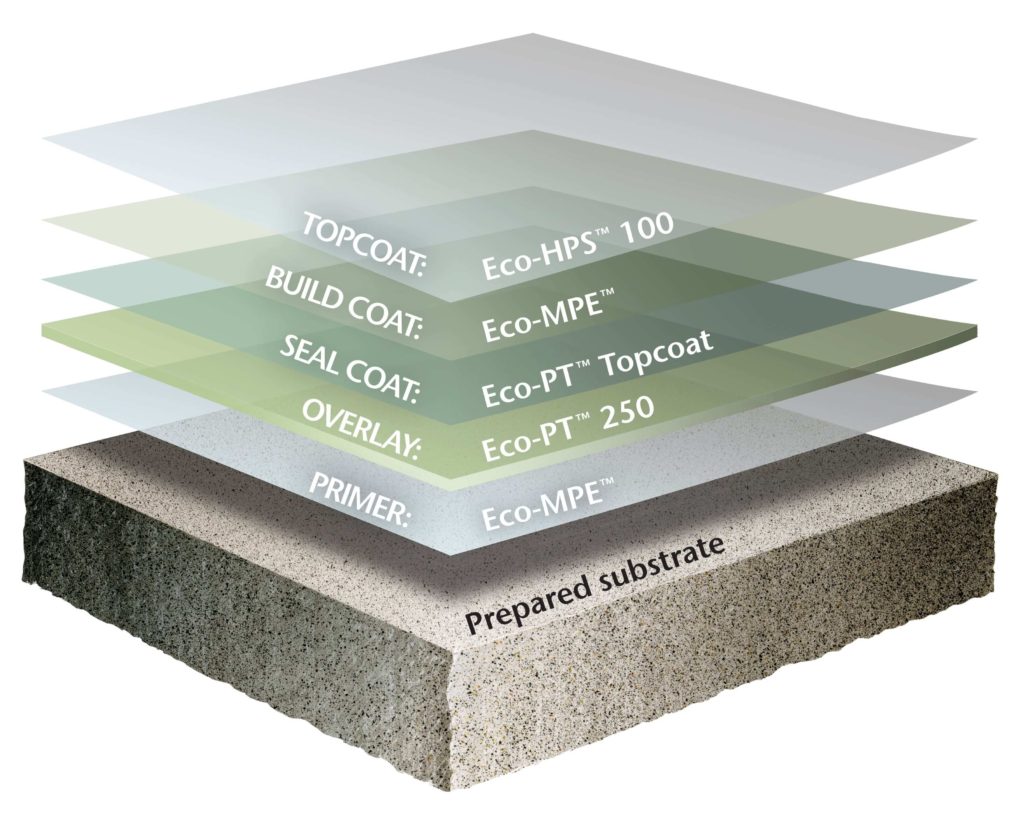

A nominal 1/4” epoxy mortar system used to resurface eroded interior concrete floors with a UV-stable urethane topcoat with a gloss finish

Key Features of the HD-HPS System

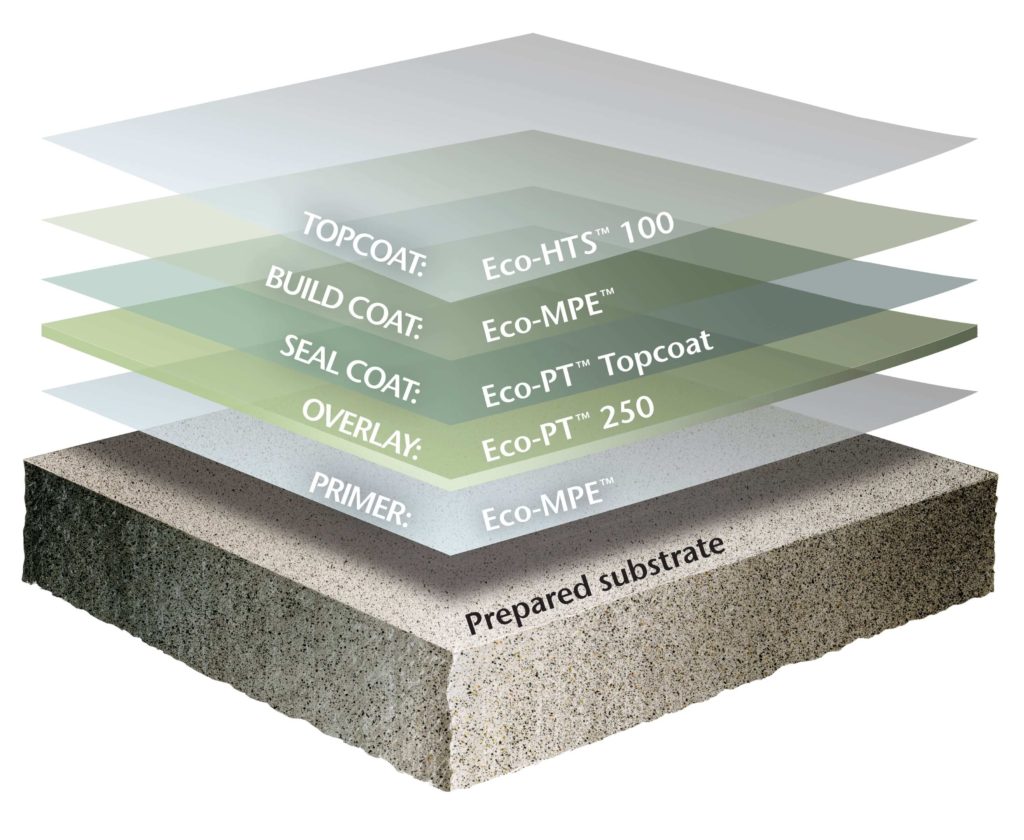

A nominal 1/4” epoxy mortar system used to resurface eroded interior concrete floors with a UV-stable urethane topcoat with a satin finish for long-lasting durability

Key Features of the HD-HTS System

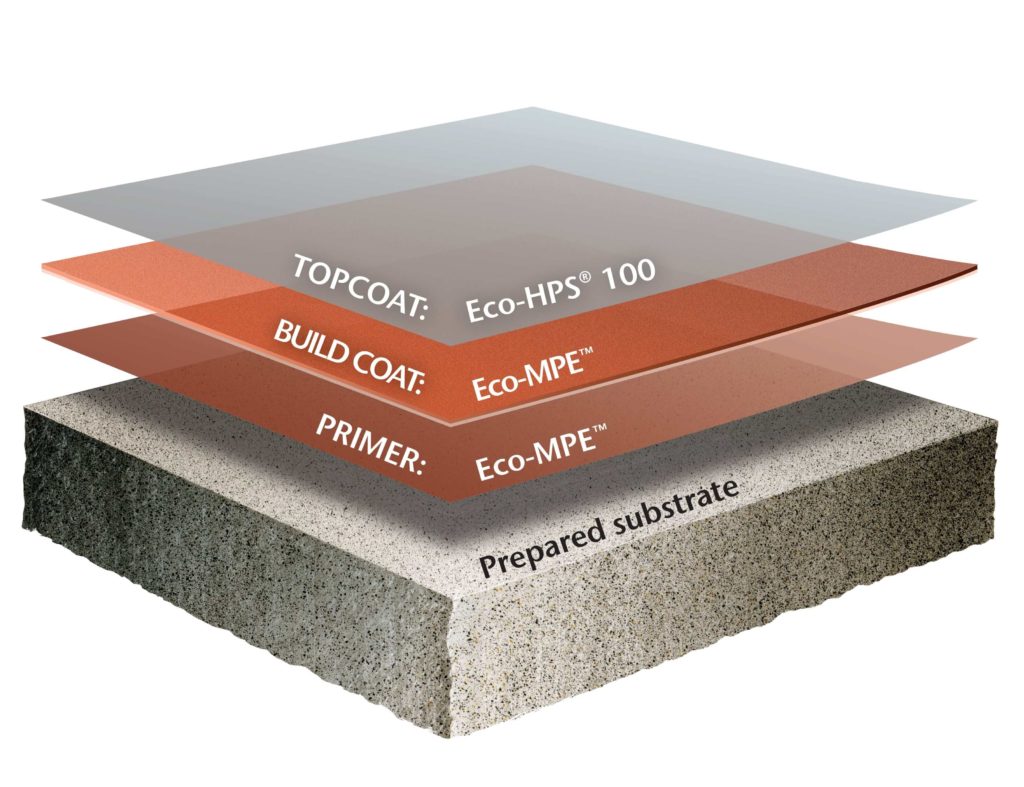

A nominal 25 mil system, using Eco- MPE™ as the epoxy primer and build coat and Eco-HPS® 100 as the light stable and chemical resistant topcoat with a gloss finish

A nominal 25 mil system, using Eco- MPE™ as the epoxy primer and build coat and Eco-HPS® 100 as the light stable and chemical resistant topcoat with a gloss finish

A nominal 25 mil system, using Eco- MPE™ as the epoxy primer and build coat and Eco-HTS™ 100 as the durable, light stable and chemical resistant topcoat with a satin finish

Key Features of the HTS System

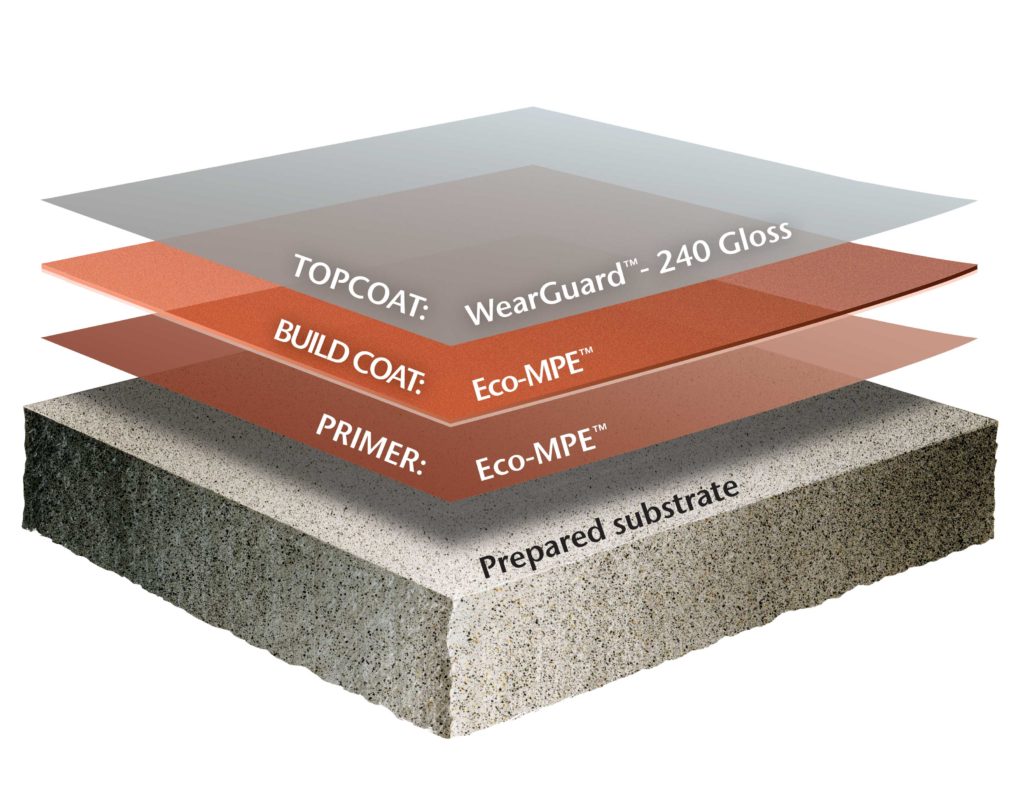

A nominal 25 mil system, using Eco-MPE™ as the epoxy primer and build coat and WearGuard-240 Gloss as an economical topcoat with a gloss finish

Key Features of the WearGuard-240 Gloss System

Image-conscious aviation facilities

typically specify a high-gloss coating that is easy to clean and

delivers excellent light reflectivity. Without proper protection, the

introduction of grease, solvents and harsh cleaning solutions can cause

concrete floors to become dull, stained and unsightly.

Beyond great aesthetics, floor coatings for the aviation and aerospace industry may also require:

Flooring for aviation and aerospace

facilities must perform under the rigorous conditions of daily

operations and cleanings, yet retain its beautiful, highly reflective

finish over the long term. A well selected and installed flooring system

can stand up to frequent chemical spills and wear-and-tear, while

improving the safety of building occupants and providing an elegant

backdrop for prized aircraft.

Different facilities in the aviation and aerospace industry have varying flooring needs. Our high performance urethane floor coating systems and topcoats can be easily customized to suit the unique requirements of specific areas or departments. Industry-renowned, this cutting-edge resinous flooring is ideal for a variety of uses and operations within aviation and aerospace facilities including:

Thanks to our broad selection of systems, virtually every floor within aviation and aerospace facilities can receive optimal protection and aesthetics.

Formulated for each individual facility and its requirements, Tennant’s experienced R&D department has developed floor coating systems that offer aircraft and aerospace facility managers a solution for every flooring concern, while providing exceptional durability and a long usable life.

Customization options for our urethane floor coatings and systems include:

High performance, safety-conscious and

uniquely designed aviation flooring is within reach, installed by our

experienced, authorized flooring contractors.

Since 1870, Tennant has led the way in helping customers create a cleaner, safer and healthier world through innovative floor maintenance and coatings solutions. Today, Tennant Coatings is the industry standard in product quality, reliability and customer service.