Concrete Coatings & Restoration

Among Tennant Coatings’ most popular floor coating systems is the Eco-ShopFloor™ system. This flooring system is designed specifically to withstand the demands of a working shop or similarly hardworking facility. These facilities must withstand high levels of wear and tear, including:

We at Tennant Coatings understand the high levels of stress placed on shop floors, which is why we developed our heavy duty Eco-ShopFloor™ system with those areas specifically in mind.

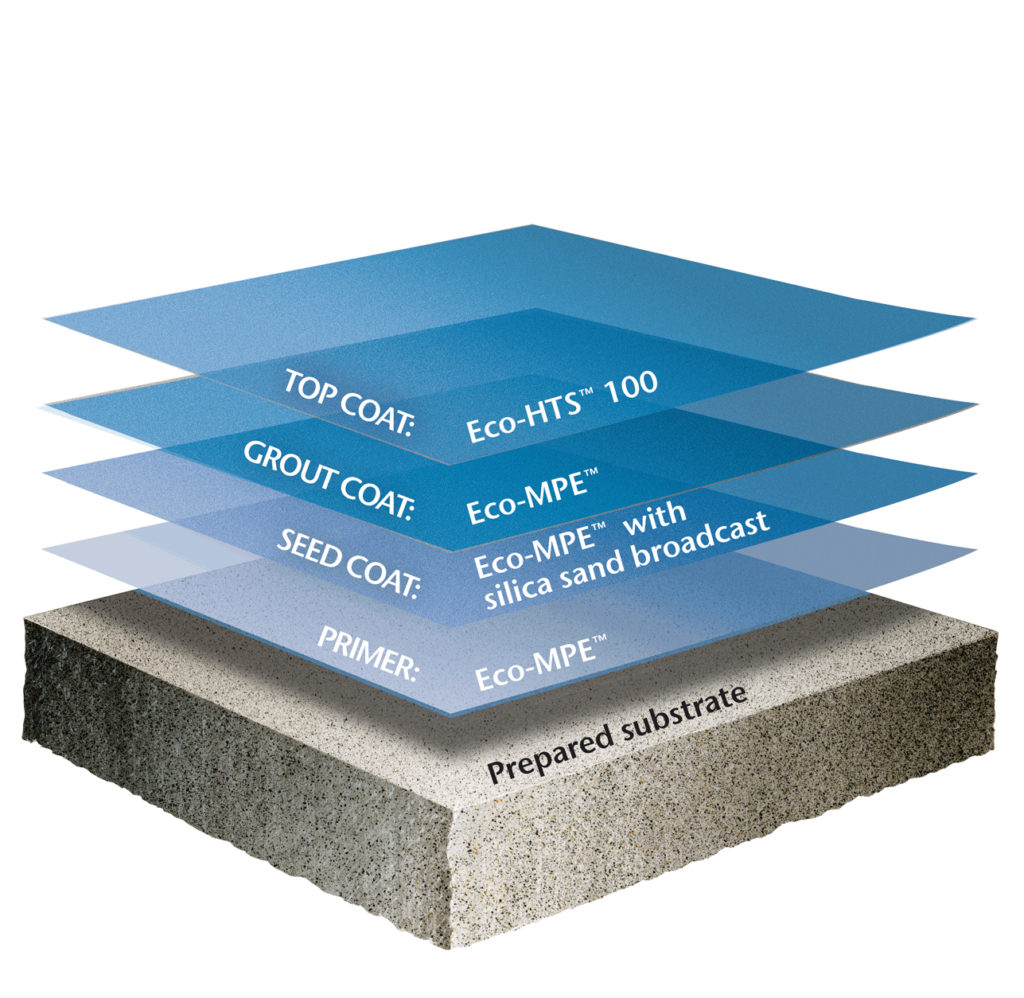

A four-coat, nomial 1/16” system, used to help withstand the high demands of a hard working facility, with a silica sand broadcast for added texture and durability, topcoated with Eco-HTS™ 100 for chemical resistance and its aliphatic properties.

Key Features of Eco-ShopFloor™ System

The Eco-ShopFloor™ is an economical flooring system that provides exceptional protection at a price that won’t break the bank. The system measures in at 1/16 of an inch and consists of four layers that work together to protect and strengthen the underlying concrete slab. Those four layers are:

In addition to its exceptional strength and durability, Eco-ShopFloor™ is a low odor option with low levels of volatile organic compounds (VOCs), which are organic compounds that can easily become gaseous and emit into the air. In addition to causing an odor, VOCs can be hazardous to human health: prolonged exposure may result in throat irritation, headaches, nausea, and damage to internal organs. While VOCs are used to make up a huge portion of paints and floor coatings, Tennant Coatings is proud to offer safe options like Eco-ShopFloor™ that are low odor and low VOC.