Concrete Coatings & Restoration

We’ve all experienced a minor electric “shock” or discharge of static electricity when touching a door handle or metal object after walking across a carpeted floor. At worst, these electric discharges are annoying or perhaps mildly painful, but what if you’re handling delicate electronic equipment that is sensitive to electrical events?.

Facilities that manufacture and repair sensitive electronics such as semiconductors and avionic instruments need comprehensive plans to protect both the equipment and employees. Oftentimes, static control floor coatings are a part of this plan.

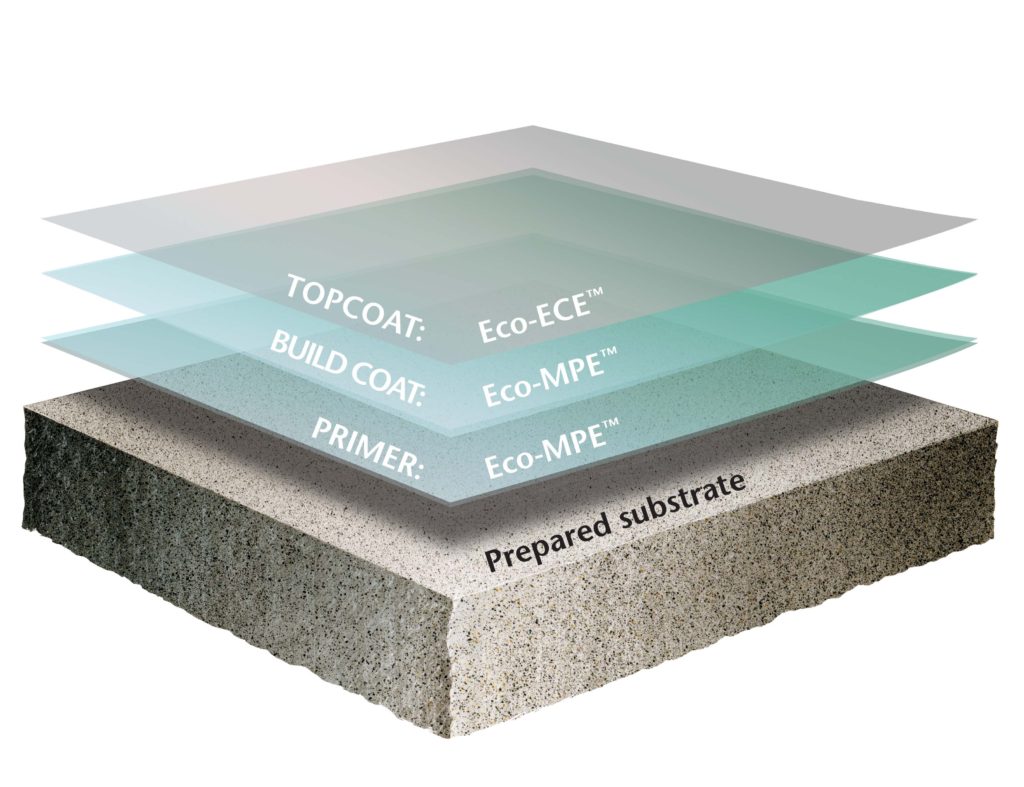

Tennant’s Eco-ECE 30 mil system is a conductive epoxy system, which uses Eco-MPE™ as the prime coat and build coat and Eco-ECE as the conductive topcoat in a gloss finish

Please contact West Pacific Coatings for more information regarding any of the Tennant products. Our sales team in Vancouver Canada can help you find the best floor Coating for your needs. [Click Here]

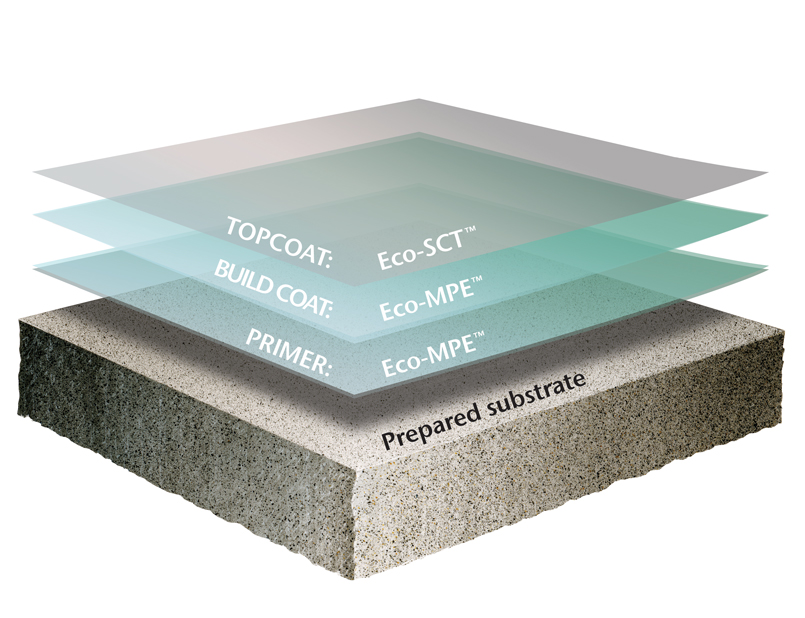

A nominal 35 mil, static dissipative system which includes an epoxy primer and an epoxy topcoat with a conductive powder and a gloss appearance

Key Features of Eco-SCT™

Please contact West Pacific Coatings for more information regarding any of the Tennant products. Our sales team in Vancouver Canada can help you find the best floor Coating for your needs. [Click Here]

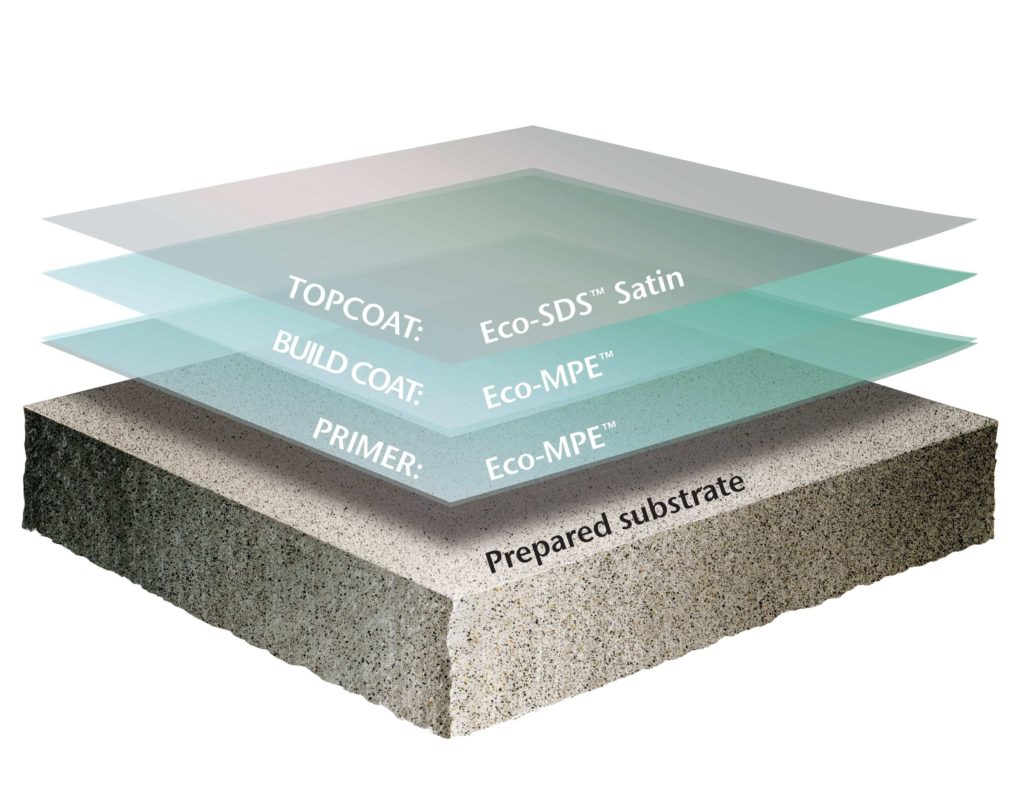

A nominal 25 mil static dissipative system with an epoxy primer and light stable urethane topcoat with a satin finish for long-lasting durability

Key Features of Eco-SDS™ Satin

Please contact West Pacific Coatings for more information regarding any of the Tennant products. Our sales team in Vancouver Canada can help you find the best floor Coating for your needs. [Click Here]

While we all come into contact with static electricity on a daily basis, it is rarely a cause for concern. But in facilities that process and manufacture sensitive electronics, explosive materials, or volatile chemicals, static electricity can pose a threat in a variety of ways.

What is Electrostatic Dissipative (ESD) and Conductive Flooring? Electrostatic dissipative flooring, also known as ESD flooring, works like a grounding rod. It is conductive at the level appropriate for allowing static electricity to safely flow through it and reach a grounding point, where the charge is then removed from the room. ESD epoxy and urethane flooring systems improve safety by allowing for the continual discharge and dissipation of a certain level of electric energy in a given space. Where do you typically use ESD and conductive flooring? ESD flooring is typically used in facilities that require protection of electronics. Conductive flooring is typically used in potentially explosive settings. Therefore so it is important to consider Tennant’s various static control flooring systems if your facility handles sensitive electronics or volatile, unstable materials.

At Tennant Coatings, we are proud to offer high quality flooring systems that meet the demands of most commercial and industrial settings. Ask our team about options for to receive the same level of quality and care you’ve come to expect from Tennant Company floor cleaning systems.

For more information, please visit our new website

https://www.westpacificcoatings.com/