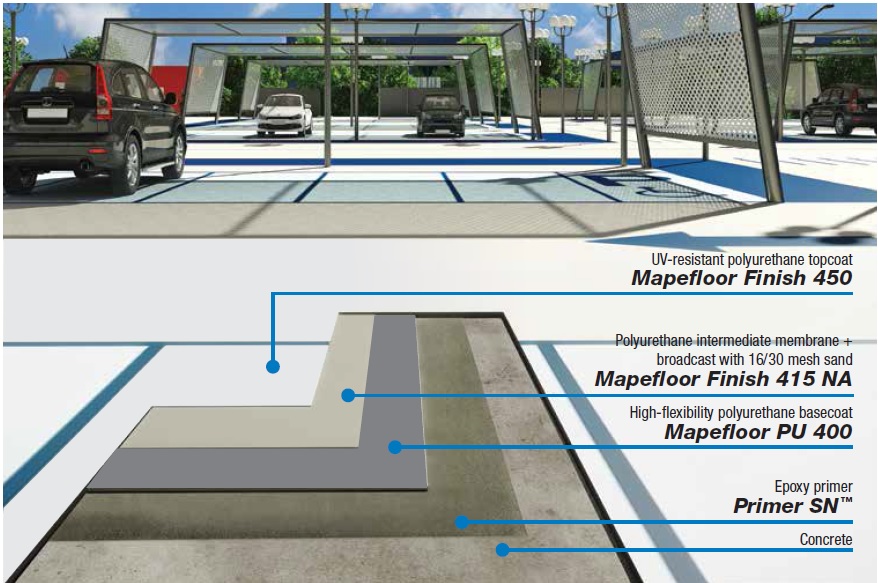

Parking Deck System

Mapefloor Parking Deck System

Two-component, flexible polyurethane system designed to provide an elastomeric waterproofing membrane for heavy pedestrian and vehicular traffic.

Where to use

The Mapefloor parking deck system may be used for the following applications:

- Multi-story parking garages and areas with heavy vehicular traffic

- Concrete surfaces requiring flexibility as well as high resistance to wear and abrasion

- Suspended pedestrian walkways and balconies

- For waterproofing interior and exterior concrete surface

Performance characteristics

The Mapefloor parking deck system provides surfaces with the following:

- High flexibility with good crack-bridging capacity

- High resistance to wear and abrasion for long-lasting performance

- Low odor and VOC compliance for use in interior occupied environments

- Easy cleanability

- Excellent resistance to chemical agents, including diluted acids, bases, oil, fuel and salts

- Highly attractive wearing surface, in as little as one coat

UV

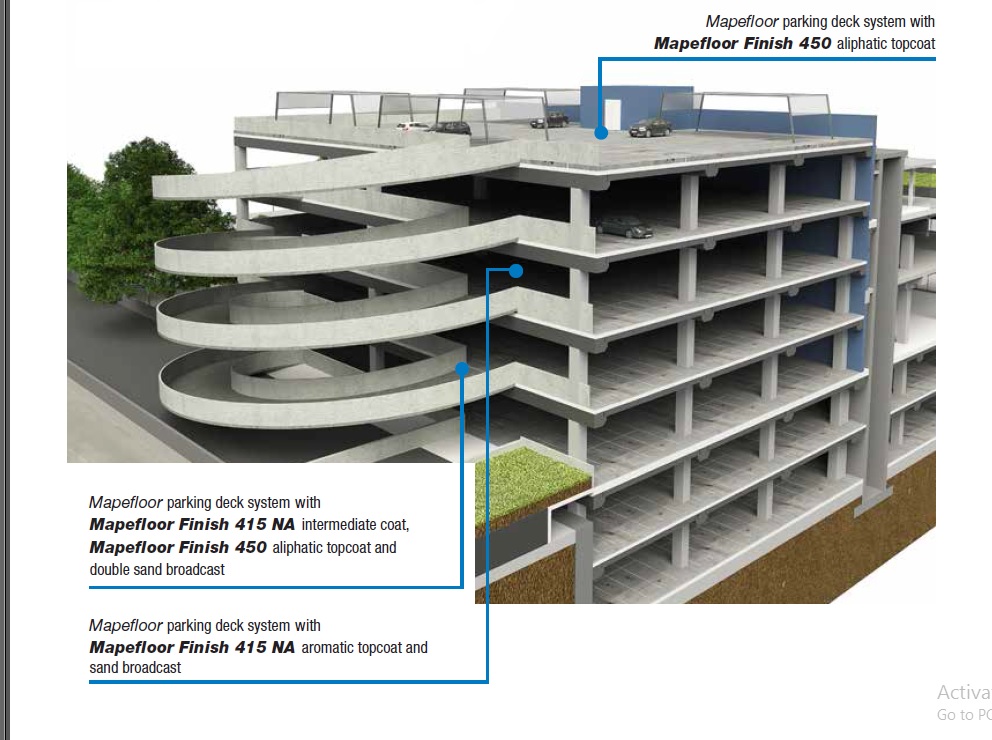

Application examples for Mapefloor Parking Deck System

- Parking decks are negatively affected by

wear and abrasion, aggressive chemical agents, water and salt intrusion,

harmful atmospheric agents and extreme temperature variations. The solution is

to provide an impermeable, non-slip surface that will resist the wear caused by

vehicular traffic, in addition to the oil, fuel and salts that deck surfaces

experience. Flexible enough to allow for above-grade movements in the

substrate, the surface treatment must also have crack-bridging properties to

prevent water and de-icing salts from infiltrating the slab.

- Access ramps of the parking structure must

be equally protected with a highly slip-resistant and abrasionresistant surface

to handle the multiple stops and turns on these ramps. They must also be

protected against water and dissolved salts penetrating the slabs.

- Intermediate parking decks must be

protected from mechanical wear and aggressive chemicals, and be able to prevent

de-icing salt intrusion into the substrate. Intermediate decks must also handle

movement caused by expansion and contraction of the substrate, although not to

the same degree as the top deck.

- Decks on and below grade require the same

resistance to aggressive chemicals and wear as the upper decks, but they are

generally less impacted by slab movement and possible structural failure than

above-grade decks.

Product application

- For

slabs above grade, apply Primer SN at a thickness of 9 to 15 mils DFT or a rate of 105 to 178 sq.

ft. per U.S. gal. (2,57 to 4,36 m2 per L).

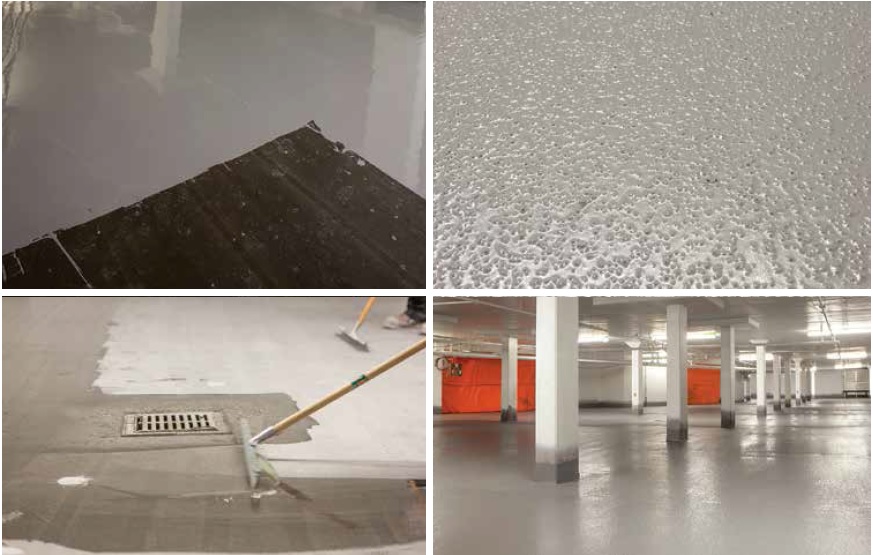

- Pour

the mixed Mapefloor PU 400 onto the surface of

the properly prepared substrate and spread evenly and uniformly with a rubber

squeegee at a depth of 25 mils or a rate of 60 sq. ft. per U.S. gal. (1,47 m2 per L). Apply Mapefloor PU 400 within 24 hours of application of Primer SN. Re-prime if Mapefloor PU 400 cannot be applied within

24 hours. Steep slopes may require thinner, multiple passes of coating to

achieve the necessary thickness.

- Allow

Mapefloor PU 400 to cure (for about

3 to 10 hours at 75؛F [24؛C]).

Then, pour mixed Mapefloor Finish 450 or Mapefloor Finish 415 NA onto the previous

layer of Mapefloor PU 400 and spread evenly

and uniformly with a rubber squeegee at a depth of 15 mils or a rate of 106 sq.

ft. per U.S. gal. (2,60 m2 per L). Apply Mapefloor Finish 450

or Mapefloor Finish 415 NA within 8 to 10

hours of application of Mapefloor PU 400.

- Immediately

broadcast 16/30 mesh silica quartz sand aggregate – evenly distributed – into the wet coating at a rate of 10 to 15 lbs. per 100 sq. ft.

(or 0,49 to 0,73 kg per m2), and back-roll. When the coating is dry, remove loose, excess

aggregate by blowing, sweeping or vacuuming. Allow 8 to 10 hours for curing.

5. For heavy-duty areas such as spiraled ramps, turn areas and ticket booths, apply an additional coat of Mapefloor Finish 450 or Mapefloor Finish 415 NA at 15 mils or a rate of 106 sq. ft. per U.S. gal. (2,60 m2 per L). Broadcast a second layer of 16/30 mesh silica quartz sand at a rate of 10 to 15 lbs. per 100 sq. ft. (or 0,49 to 0,73 kg per m2) and back-roll. When the coating is dry, remove loose, excess aggregate. Heavy-duty areas should average 55 mils, excluding aggregate and primer. All other areas (nonheavy-duty) should average 40 mils, excluding aggregate and primer.

Installation phases

- Application of the primer (Primer SN)

- Spreading the flexible polyurethane basecoat (Mapefloor PU 400)

- Spreading the polyurethane topcoat (Mapefloor Finish 415 NA or Mapefloor Finish 450)

- Broadcasting aggregate to refusal and back-rolling

Broadcast

Please contact West Pacific Coatings for more information regarding any of the MAPEI products. Our sales team in Vancouver Canada can help you find the best floor Coating for your needs. [Click Here]